Buick Regal: DTC P2814 or P2815

Diagnostic Instructions

- Perform the Diagnostic System Check prior to using this diagnostic procedure: Refer to Diagnostic System Check - Vehicle

- Review the description of Strategy Based Diagnosis: Refer to Strategy Based Diagnosis

- An overview of each diagnostic category can be found here: Refer to Diagnostic Procedure Instructions

DTC Descriptor

DTC P2814

Pressure Control Solenoid Valve 7 Control Circuit Low Voltage

DTC P2815

Pressure Control Solenoid Valve 7 Control Circuit High Voltage

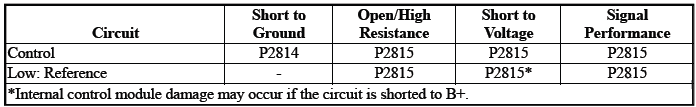

Diagnostic Fault Information

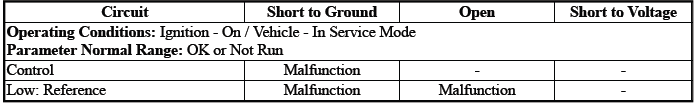

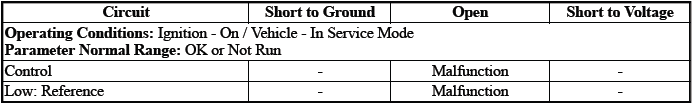

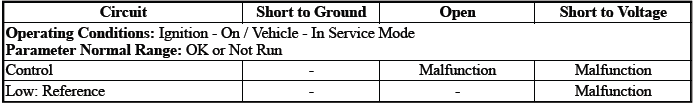

Typical Scan Tool Data

Pressure Control Solenoid Valve 7 Control Circuit Low Voltage Test Status

Pressure Control Solenoid Valve 7 Control Circuit Open Test Status

Pressure Control Solenoid Valve 7 High Voltage Test Status

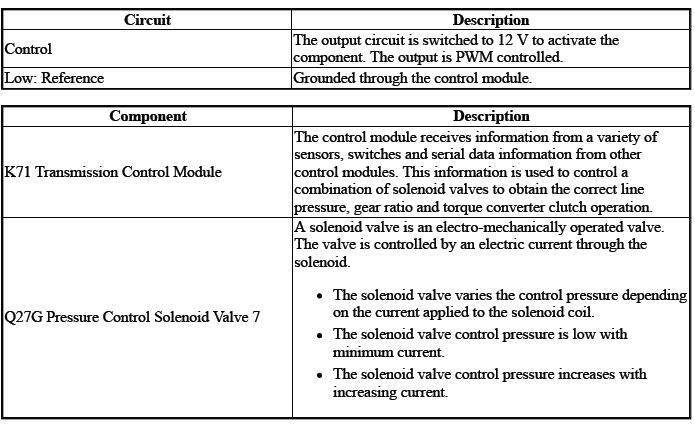

Circuit/System Description

The solenoid valve controls the flow of transmission fluid to the hydraulic actuator that controls the C1 clutch. - During an autostart or autostop event

Conditions for Running the DTC

Ignition Voltage=9 to 32 V

DTCs run continuously when the above conditions are met for greater than 2 s.

Conditions for Setting the DTC

Control circuit=Commanded state does not match the actual state

Actions Taken When the DTC Sets

DTCs P2814, P2815 are Type B DTCs.

Autostart/Autostop=Disabled

Conditions for Clearing the DTC

DTCs P2814, P2815 are Type B DTCs.

Reference Information

Schematic: Reference

Refer to Automatic Transmission Controls Wiring Schematics

Connector End View: Reference

Refer to Component Connector End View Index

Component View: Reference

Refer to Disassembled Views

Description and Operation

Refer to Transmission General Description

Electrical Information: Reference

- Refer to Circuit Testing

- Refer to Connector Repairs

- Refer to Testing for Intermittent Conditions and Poor Connections

- Refer to Wiring Repairs

DTC Type: Reference

Refer to Powertrain Diagnostic Trouble Code (DTC) Type Definitions

Scan Tool: Reference

Refer to Control Module: References

Circuit/System Verification

1. Ignition - On / Vehicle - In Service Mode

2. Perform the scan tool control function:Auxiliary Transmission Fluid Pump - Enable & Disable

Verify the scan tool parameter:

- Pressure Control Solenoid Valve 7 High Voltage Test Status= OK or Not Run

- Pressure Control Solenoid Valve 7 Control Circuit Low Voltage Test Status= OK or Not Run

- Pressure Control Solenoid Valve 7 Control Circuit Open Test Status= OK or Not Run

- If not the specified state

Refer to Circuit/System Testing

- Go to next step: If the specified state

3. Perform the scan tool control function:Auxiliary Transmission Fluid Pump - Enable & Disable

Verify the component produces a clicking sound:Q27G Pressure Control Solenoid Valve 7

- If the component does not produce a sound

Refer to Circuit/System Testing

- Go to next step: If the component produces a sound

4. Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

5. Verify the DTC does not set.

- If the DTC sets

Refer to Circuit/System Testing

- Go to next step: If the DTC is not set

6. All OK.

Circuit/System Testing

NOTE: It may take up to 2 min for all vehicle systems to power down before an accurate ground or low reference circuit continuity test can be performed.

1. Ignition/Vehicle & All vehicle systems - Off

NOTE: Twisting or tilting of the transmission control module electrical connector while disconnecting may result in bent or misaligned electrical terminal pins.

2. Remove the component:K71 Transmission Control Module

NOTE: The component's temperature should be 19 to 21ºC (66 to 70ºF) while testing.

3. Test for 5.0 to 5.6 ohms between the test points:Control circuit terminal 30 & Low: Reference circuit terminal 29

- If not between 5.0 and 5.6 ohms

- Remove the component:Control Valve Body Cover

- Disconnect the electrical connector:Q27G Pressure Control Solenoid Valve 7

- Test for less than 2 ohms between the test points:

- Control circuit terminal 2@Component harness & Control circuit terminal 30@Control module harness

- Low: Reference circuit terminal 1@Component harness & Low: Reference circuit terminal 29@Control module harness

- If 2 ohms or greater - Replace the component:Automatic Transmission Wiring Harness

- If less than 2 ohms - Replace the component:Control Valve Body

- Go to next step: If between 5.0 and 5.6 ohms

4. Test for infinite resistance between the test points:

- Control circuit terminal 30 & Transmission Case

- Low: Reference circuit terminal 29 & Transmission Case

- If less than infinite resistance

- Remove the component:Control Valve Body Cover

- Disconnect the electrical connector:Q27A Pressure Control Solenoid Valve 1

- Test for infinite resistance between the test points:

- Control circuit terminal 2@Component harness & Transmission Case

- Low: Reference circuit terminal 1@Component harness & Transmission Case

- If less than infinite resistance - Replace the component:Automatic Transmission Wiring Harness

- If infinite resistance - Replace the component:Control Valve Body

- Go to next step: If infinite resistance

5. Test or replace the component:K71 Transmission Control Module

Component Testing

1. Ignition/Vehicle - Off

2. Disconnect the electrical connector:Q27G Pressure Control Solenoid Valve 7

NOTE: The component's temperature should be 19 to 21ºC (66 to 70ºF) while testing.

3. Test for 5.0 to 5.6 ohms between the test points:Control terminal 2 & Low: Reference terminal 1

- If not between 5.0 and 5.6 ohms

Replace the component:Control Valve Body

- Go to next step: If between 5.0 and 5.6 ohms

4. Test for infinite resistance between the test points:Each terminal of the component & The component's housing

- If less than infinite resistance

Replace the component:Control Valve Body

- Go to next step: If infinite resistance

5. All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair: Refer to Diagnostic Repair Verification

- Refer to Control Valve Body Replacement

- Refer to Wiring Harness Wire Replacement

- For control module replacement, programming, and setup: Refer to Control Module: References