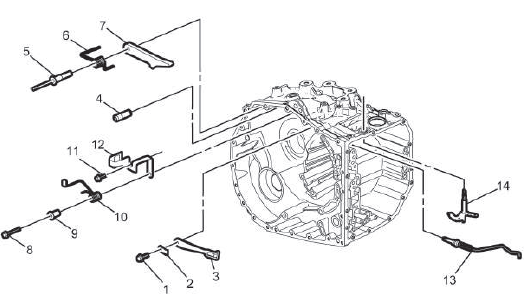

Buick Regal: Manual Shift Detent Lever and Park Pawl Removal

Park Components Removal

Park Components Removal

- Manual Shift Detent Bolt

- Automatic Transmission Control Lever Detent Spring

- Manual Shift Detent Lever Spring

- Park Pawl Lockout Pin

- Park Pawl Shaft

- Park Pawl Spring

- Park Pawl

- Park Pawl Actuator Bracket Bolt

- Park Pawl Pin Spring Guide Sleeve

- Park Pawl Actuator Lever Spring

- Park Pawl Actuator Bracket Bolt

- Park Pawl Actuator Bracket

- Park Pawl Actuator Rod

- Manual Shift Shaft Lever

Lubricant Fluid Pipe Removal

- Front Differential Transfer Drive Gear Fluid Passage Tube Bolt[2x]

- Automatic Transmission Control Wiring Harness Clamp

- Lubricant Fluid Pipe Retainer

- Lubricant Fluid Pipe

- Torque Converter and Differential Housing Bolt

- Automatic Transmission Vent Baffle Cover

- Torque Converter and Differential Housing Bolt

- Automatic Transmission Vent Baffle Cover

FINAL DRIVE PINION AND RING GEAR REMOVAL

- Final Drive Pinion and Ring Gear

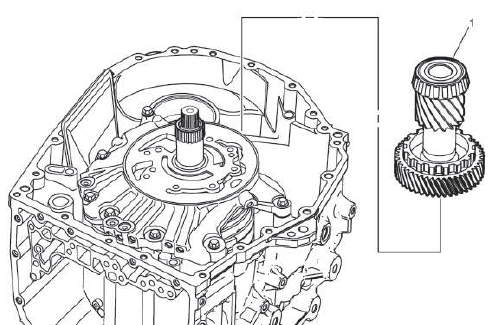

COUNTER DRIVE GEAR REMOVAL

- Front Differential Transfer Drive Gear Fluid Passage Tube Bolt

- Automatic Transmission Control Wiring Harness Clamp

NOTE: It may be necessary to remove the automatic transmission control wiring harness clamp to access all the bolts.

- Center Support Bolt [6x]

- Counter Drive Gear

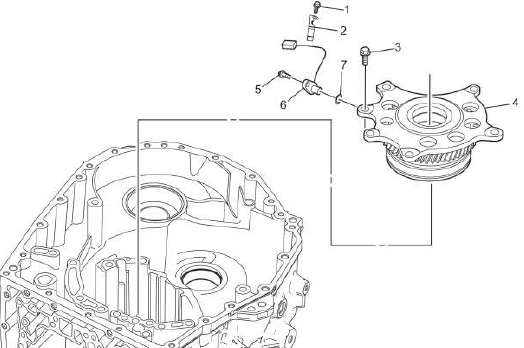

- Automatic Transmission Intermediate Speed Sensor Bolt

- Vehicle Speed Sensor

- Vehicle Speed Sensor Spacer

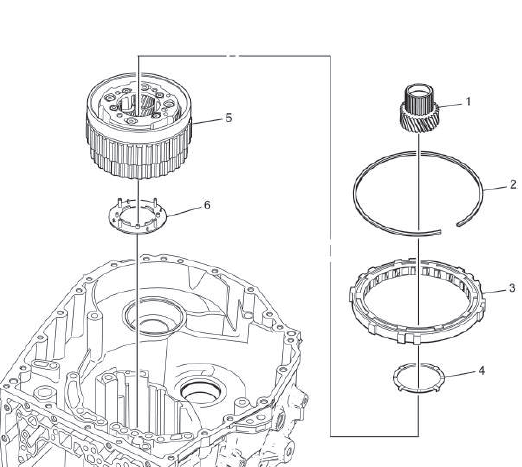

OVERRUN CLUTCH AND REAR CARRIER REMOVAL

- Sun Gear

- Overrun Clutch Retaining Ring

- Overrun Clutch

- Rear Carrier Thrust Washer

- Rear Carrier

- Rear Carrier Thrust Washer

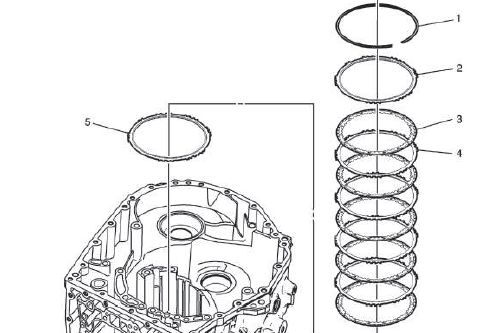

1ST AND REVERSE CLUTCH BACKING PLATE REMOVAL

- 1-Reverse Clutch Backing Plate Retaining Ring

- Forward Clutch Backing Plate

- 1st and Reverse Clutch Plate - Friction Plate

- 1st and Reverse Clutch Plate

- 1st and Reverse Clutch Backing Plate

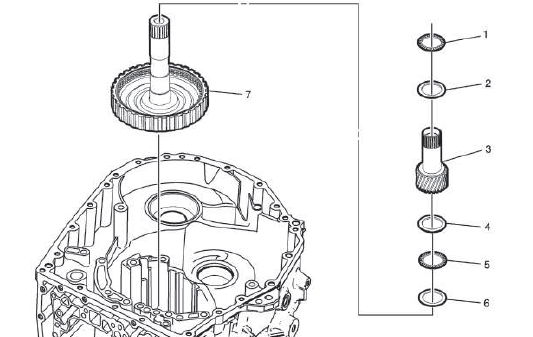

DIRECT CLUTCH ASSEMBLY REMOVAL

- Rear Sun Gear Thrust Bearing

- Rear Sun Gear Thrust Bearing Race

- Rear Sun Gear

- Rear Sun Gear Thrust Bearing Race

- Direct Clutch Bearing

- Direct Clutch Hub Thrust Bearing Race

- Direct Clutch

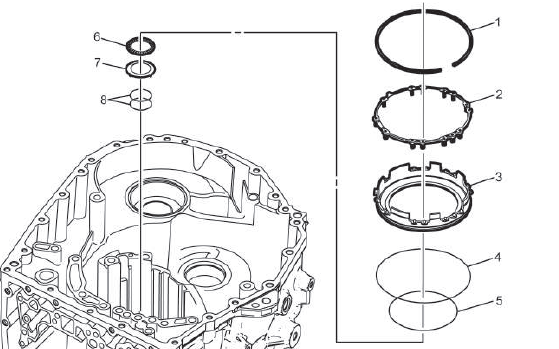

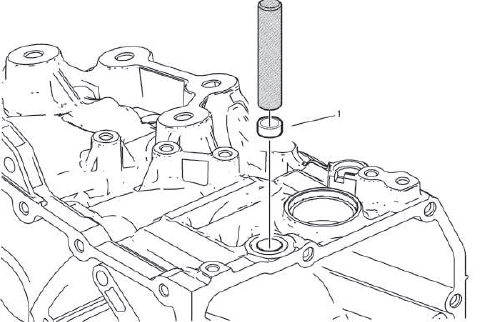

LOW AND REVERSE CLUTCH PISTON REMOVAL

- 1-Reverse Clutch Spring Retaining Ring

- 1-Reverse Clutch Spring

- Low and Reverse Clutch Piston

Procedure

Apply compressed air to the case passage to remove the low and reverse clutch piston.

- Low and Reverse Clutch Application Ring

- Low and Reverse Clutch Application Ring

- 2nd Clutch Housing Rear Bearing

- Direct Clutch Hub Thrust Bearing Race

- Direct Clutch Fluid Seal Ring [2x]

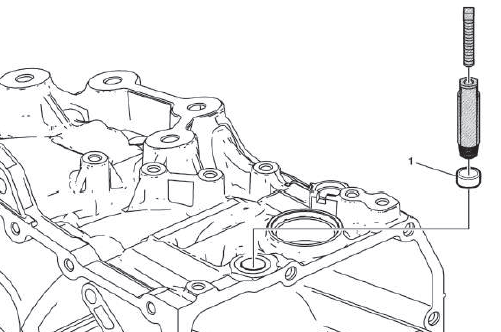

MANUAL SHIFT SHAFT SEAL REMOVAL

- Manual Shift Shaft Seal

Special Tools

DT-43911 Selector Shaft Seal Remover

For equivalent regional tools, refer to Special Tools.

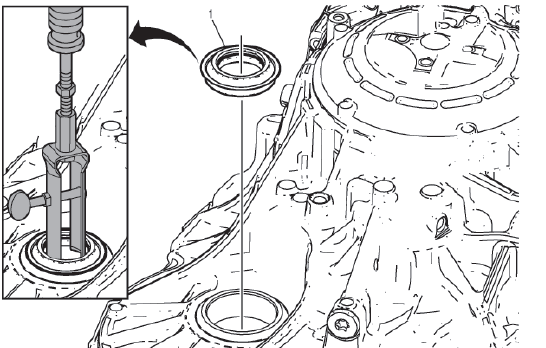

FRONT WHEEL DRIVE SHAFT OIL SEAL REMOVAL - RIGHT SIDE

- Front Wheel Drive Shaft Oil Seal - Right Side

Special Tools

- DT-26941 Remover

- GE-6125-1B Slide Hammer with Adapter

For equivalent regional tools, refer to Special Tools.

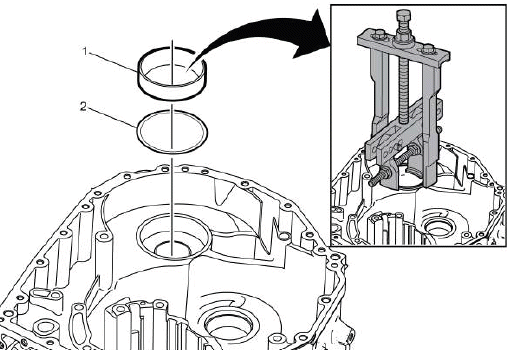

DIFFERENTIAL BEARING RACE REMOVAL

- Differential Bearing Race

Special Tools

- DT-45124 Removal Bridge

- DT-45124-9 Puller Leg

- DT-51919 Bearing Race Remover

Equivalent regional tools: Refer to Special Tools.

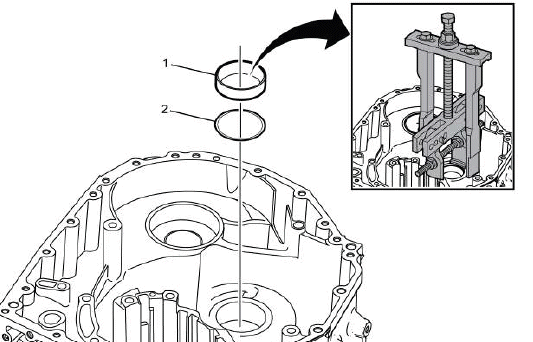

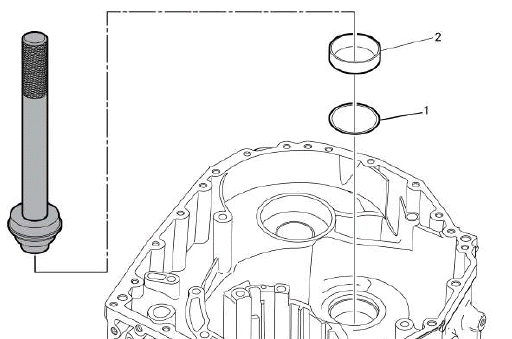

COUNTER GEAR THRUST BEARING RACE REMOVAL

- Counter Gear Thrust Bearing Race

Special Tools

- DT-45124 Removal Bridge

- DT-45124-9 Puller Leg

- DT-51919 Bearing Race Remover

Equivalent regional tools: Refer to Special Tools

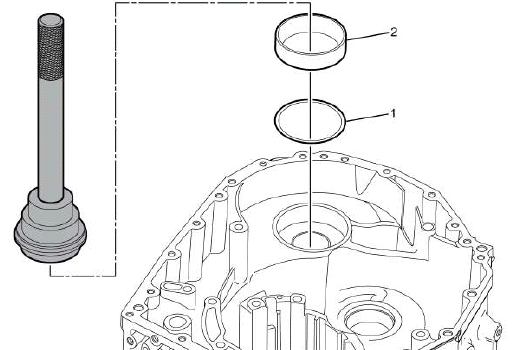

COUNTER GEAR THRUST BEARING RACE INSTALLATION

- Counter Gear Thrust Bearing Race

Special Tools

- DT-51918 Bearing Race Installer

- GE-8092 Driver Handle

For equivalent regional tools, refer to Special Tools.

DIFFERENTIAL BEARING RACE INSTALLATION

- Differential Bearing Race

Special Tools

- DT-51918 Bearing Race Installer

- GE-8092 Driver Handle

For equivalent regional tools, refer to Special Tools.

FRONT WHEEL DRIVE SHAFT OIL SEAL INSTALLATION - RIGHT SIDE

- Front Wheel Drive Shaft Oil Seal - Right Side

Special Tools

- DT-50298 Axle Seal Installer

- GE-8092 Driver Handle

For equivalent regional tools, refer to Special Tools.

MANUAL SHIFT SHAFT SEAL INSTALLATION

- Manual Shift Shaft Seal

Special Tools

DT-49101 Seal Installer

For equivalent regional tools, refer to Special Tools.