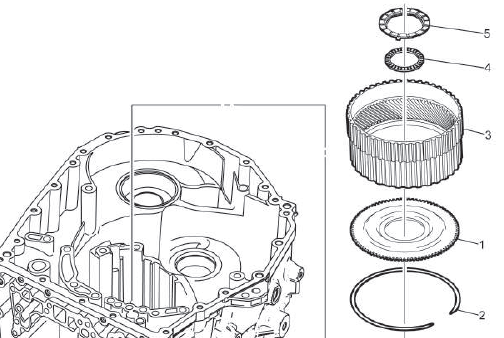

Buick Regal: Front Internal Gear Installation

- Input Carrier Flange

- Forward Clutch Backing Plate Retaining Ring

- Front Internal Gear

NOTE: Rotate to index the clutch plate and ensure seated.

- Front Carrier Thrust Bearing

- Front Carrier Thrust Bearing Race

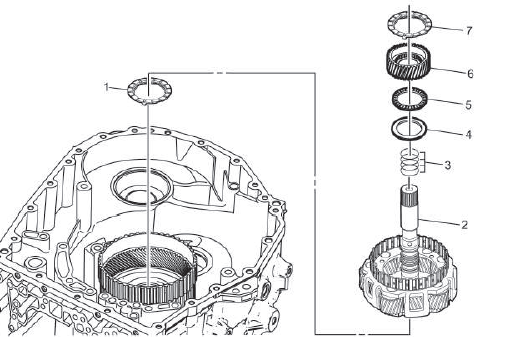

FRONT CARRIER INSTALLATION

- Sun Gear Rear Thrust Bearing Race

- Front Carrier

- Input Shaft Fluid Seal Ring[4x]

NOTE: Remove and DISCARD the seal.

- Front Carrier Thrust Bearing Race

- Sun Gear Thrust Bearing

- Front Sun Gear

NOTE: Groove side up.

- Automatic Transmission Fluid Pump Shaft Thrust Washer

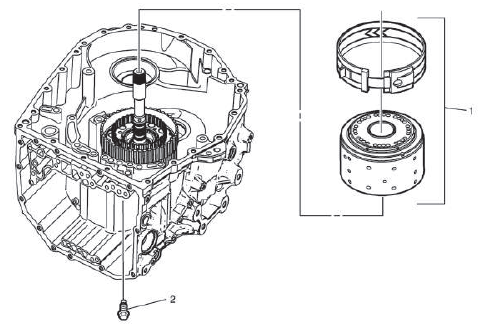

3RD CLUTCH INSTALLATION

- 3rd Clutch

NOTE: Line up the fiber plates to help seat, will have to rotate and rock to get to fully seat in place.

- Automatic Transmission Case Bolt (Band Anchor)

CAUTION: Refer to Fastener Caution.

Tighten 167 N.m (123 lb ft)

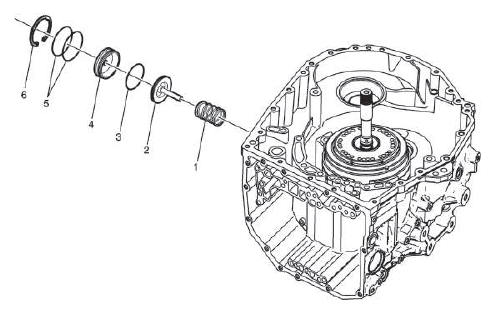

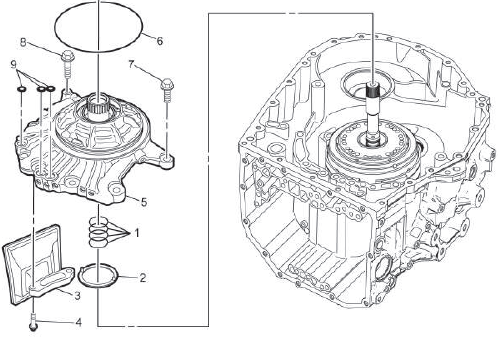

FORWARD BAND SERVO PISTON INSTALLATION

- 2nd Clutch Accumulator Piston Spring

- Forward Band Servo Piston

NOTE: Pin on the servo piston needs to index on the band.

- Forward Clutch Accumulator Piston Fluid Seal Ring

NOTE: Install a NEW seal. Do NOT reuse the old seal.

- Forward Band Servo Cover

- 2-4 Band Servo Cover Seal (O-ring)

NOTE: Install a NEW seal. Do NOT reuse the old seal.

- 2-4 Band Servo Cover Retaining Ring

NOTE: Install a NEW retaining ring.

AUTOMATIC TRANSMISSION FLUID PUMP AND FLUID FILTER INSTALLATION

- Automatic Transmission Fluid Pump Ring[4x]

NOTE: Install NEW seals. Do NOT reuse old seals.

- Automatic Transmission Fluid Pump Shaft Thrust Washer

- Automatic Transmission Fluid Filter

NOTE: Install a NEW filter. DO NOT reuse old filter.

- Automatic Transmission Fluid Filter Bolt [2x]

CAUTION: Refer to Fastener Caution.

Tighten 5 N.m (44 lb in)

- Automatic Transmission Fluid Pump

NOTE: Ensure the 3 black seals are on the fluid pump.

- Automatic Transmission Fluid Pump Seal

NOTE: Install a NEW seal. Do NOT reuse the old seal.

- Automatic Transmission Fluid Pump Bolt [5x]

Tighten 25 N.m (18 lb ft)

- Automatic Transmission Fluid Pump Bolt [2x]

Tighten 25 N.m (18 lb ft)

- Automatic Transmission Fluid Pump Seal[3x]

NOTE: Install NEW seals. Do NOT reuse old seals.

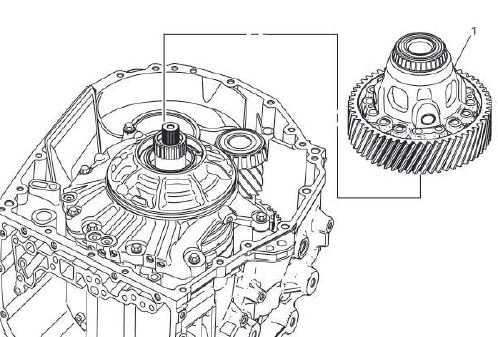

DIFFERENTIAL ASSEMBLY INSTALLATION

- Differential

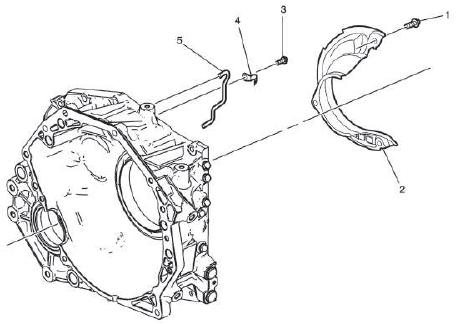

TORQUE CONVERTER AND DIFFERENTIAL HOUSING ASSEMBLY DISASSEMBLE

- Automatic Transmission Fluid Baffle Bolt [2x]

- Automatic Transmission Fluid Baffle

- Automatic Transmission Fluid Baffle Bolt

- Lubricant Fluid Hose Clamp

- Front Differential Transfer Drive Gear Fluid Passage Tube

FRONT WHEEL DRIVE SHAFT OIL SEAL REMOVAL - LEFT SIDE

- Front Wheel Drive Shaft Oil Seal - Left Side

Special Tools

- DT-26941 Remover

- GE-6125-1B Slide Hammer with Adapter

For equivalent regional tools, refer to Special Tools.

DIFFERENTIAL DRIVE PINION GEAR OUTER BEARING RACE REMOVAL

- Differential Drive Pinion Gear Outer Bearing Race

Special Tools

- DT-45124 Removal Bridge

- DT-45124-9 Puller Leg

- DT-51919 Bearing Race Remover

Equivalent regional tools: Refer to Special Tools

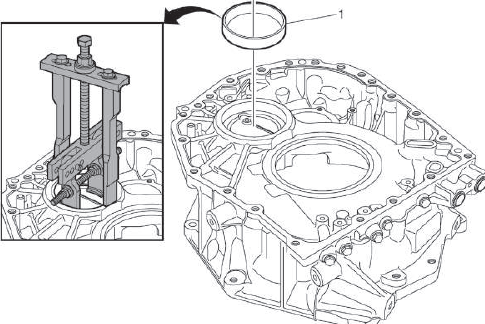

DIFFERENTIAL CARRIER BEARING RACE REMOVAL

- Differential Carrier Bearing Race

Special Tools

- DT-45124 Removal Bridge

- DT-45124-9 Puller Leg

- DT-51919 Bearing Race Remover

Equivalent regional tools: Refer to Special Tools

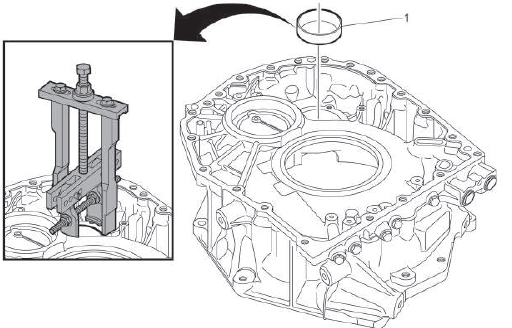

DIFFERENTIAL CARRIER BEARING RACE INSTALLATION

- Differential Carrier Bearing Race

Special Tools

- DT-51918 Bearing Race Installer

- GE-8092 Driver Handle

For equivalent regional tools, refer to Special Tools.

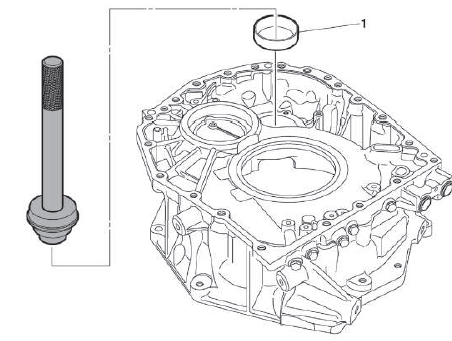

DIFFERENTIAL DRIVE PINION GEAR OUTER BEARING RACE INSTALLATION

- Differential Drive Pinion Gear Outer Bearing Race

Special Tools

- DT-51918 Bearing Race Installer

- GE-8092 Driver Handle

For equivalent regional tools, refer to Special Tools.

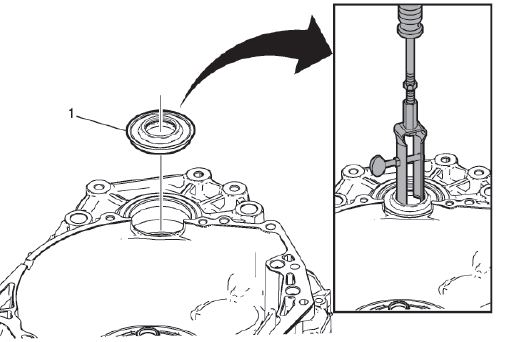

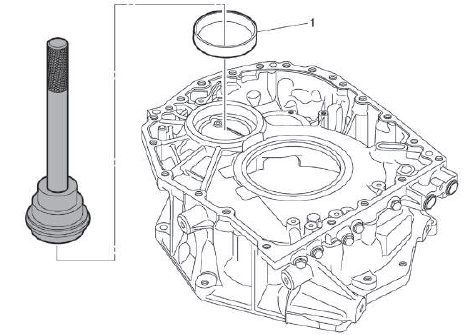

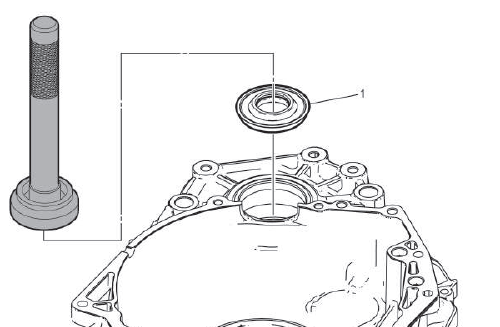

FRONT WHEEL DRIVE SHAFT OIL SEAL INSTALLATION - LEFT SIDE

- Front Wheel Drive Shaft Oil Seal - Left Side

Special Tools

- DT-52512 Axle Seal Installer

- GE-8092 Driver Handle

For equivalent regional tools, refer to Special Tools.