Buick Regal: Thread Inserts

General Purpose Thread Repair Kits.

These kits are available commercially.

Repair Procedure

1.

WARNING: Refer to Safety Glasses Warning.

NOTE: Refer to the thread repair kit manufacturer's instructions regarding the size of the drill and tap to use.

Avoid any buildup of chips. Back out the tap every few turns and remove the chips.

Determine the size, the pitch, and the depth of the damaged thread. If necessary, adjust the stop collars on the cutting tool and tap to the required depth.

2. Drill out the damaged threads. Clean out any chips.

3. Lubricate the tap with light engine oil. Tap the hole. Clean the threads.

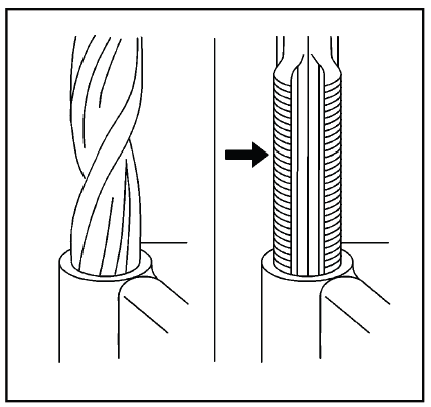

4.

Thread the thread insert onto the mandrel of the installer. Engage the tang of the insert onto the end of the mandrel.

NOTE: The insert should be flush to one turn below the surface.

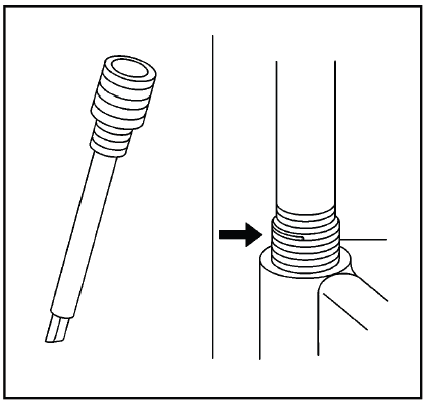

5. Lubricate the insert with light engine oil, except when installing in aluminum and install the insert.

6. If the tang of the insert does not break off when backing out the installer, break the tang off with a drift.

REGISTERED AND NON-REGISTERED TRADEMARKS

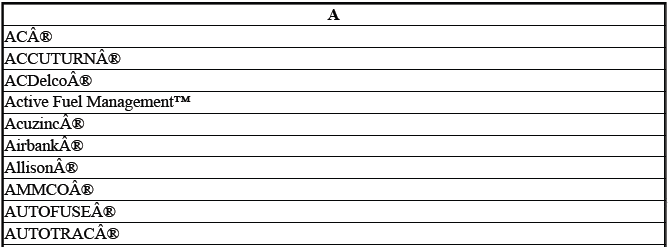

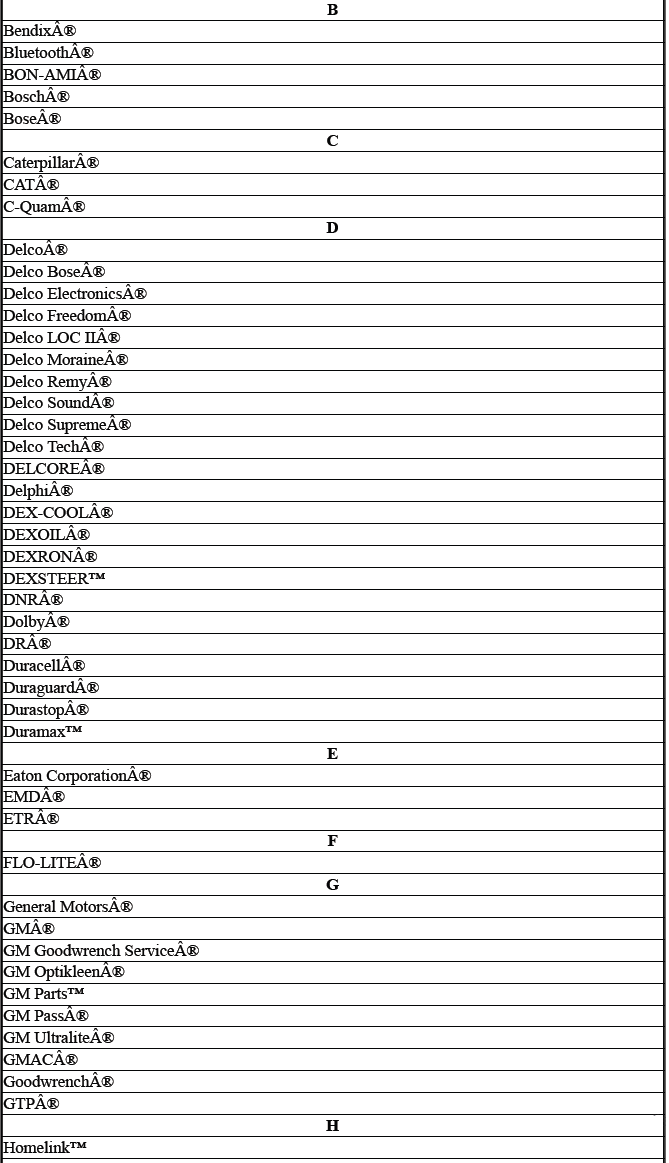

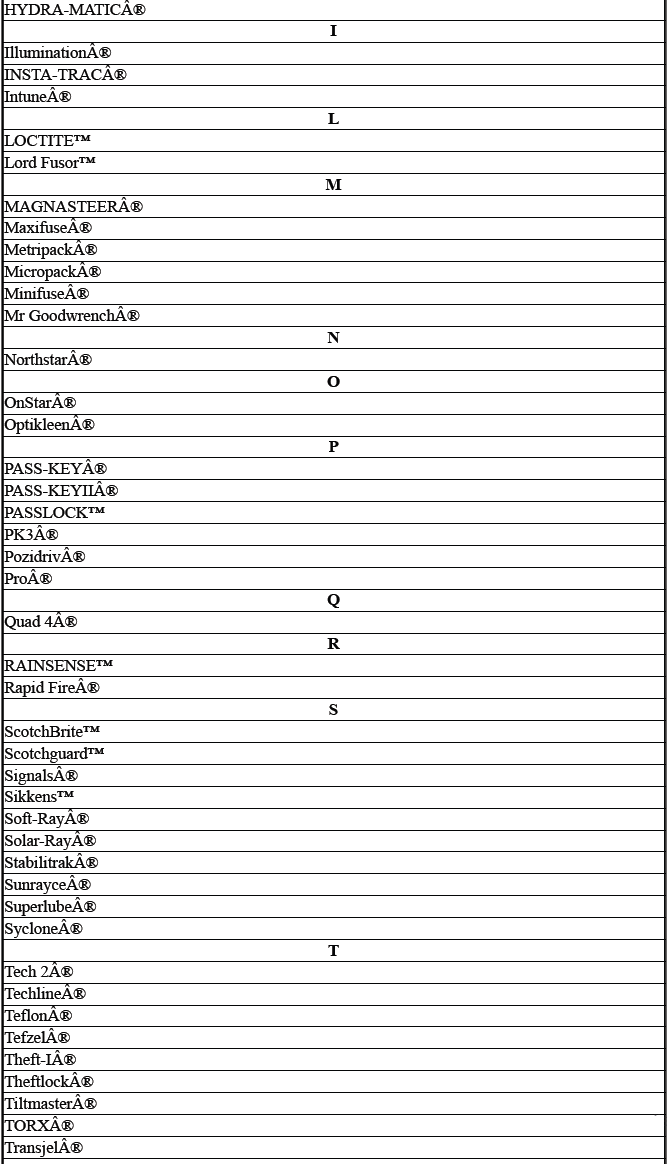

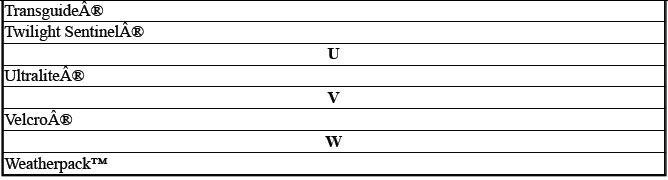

Listed below are Registered Trademarks (Â) or Non-Registered Trademarks () which may appear in this service manual.