Buick Regal: DTC P0705, P0707, P0708, or P0851

Diagnostic Instructions

- Perform the Diagnostic System Check prior to using this diagnostic procedure: Refer to Diagnostic System Check - Vehicle

- Review the description of Strategy Based Diagnosis: Refer to Strategy Based Diagnosis

- An overview of each diagnostic category can be found here: Refer to Diagnostic Procedure Instructions

DTC Descriptor

NOTE: This procedure may also diagnose malfunctions that are not detected by a DTC.

DTC P0705

Transmission Range Switch Circuit

DTC P0707

Transmission Range Switch Circuit Low Voltage

DTC P0708

Transmission Range Switch Circuit High Voltage

DTC P0851

Park/Neutral Position Switch Circuit Low Voltage

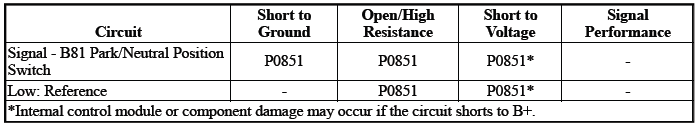

Diagnostic Fault Information

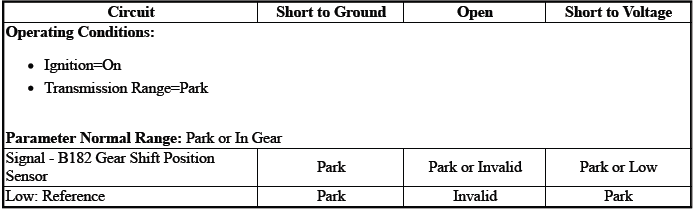

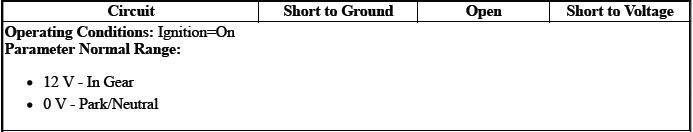

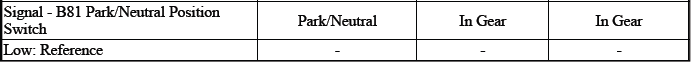

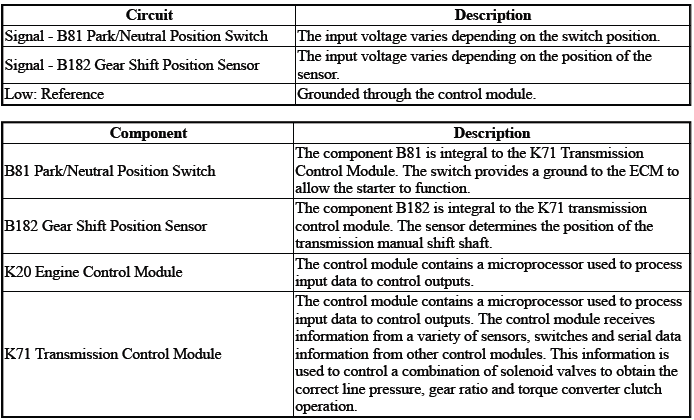

Typical Scan Tool Data

Transmission Range Switch

Park/Neutral Position Switch

Circuit/System Description

P0705, P0707, P0708

The sensor is an input to the control module K71. The control module K71 uses the information from the sensor signal B182 to determine what transmission gear range the vehicle operator selected.

The control module uses this data, along with other data, to adjust or control the following:

- Q23 Line Pressure Control Solenoid Valve

- Q27A Pressure Control Solenoid Valve 1

- Q27B Pressure Control Solenoid Valve 2

- Q27C Pressure Control Solenoid Valve 3

- Q27D Pressure Control Solenoid Valve 4

- Q27E Pressure Control Solenoid Valve 5

- Q27F Pressure Control Solenoid Valve 6

- Q27G Pressure Control Solenoid Valve 7{ If equipped }

- Q32A Shift Solenoid Valve 1

- Q32B Shift Solenoid Valve 2

- Q39A Torque Converter Clutch Pressure Control Solenoid Valve

P0851

The sensor is an input to the control module K20.

The control module uses this data, along with other data, to adjust or control the following: KR27 Starter Relay

Conditions for Running the DTC

P0705, P0707, P0708

- DTC P0851 = Not set

- K71 Transmission Control Module=Communication Enabled

- Ignition Voltage=10 to 16 V

- Service Mode=Disabled

Frequency the DTC runs=Continuously - After the running conditions are met

P0851

- Engine Torque= Greater than 75 Nm (55 lb ft)

- Ignition Voltage=10 to 16 V

- Selector Lever Position= P or N

- Throttle Position Sensor=Greater than 8%

- Vehicle Speed=Greater than 10 km/h (6 MPH)

Frequency the DTC runs=Continuously - After the running conditions are met

Conditions for Setting the DTC

P0705

Position 1 & Position 2=Not between 4.71 and 5.29 V - For greater than 1 s & For 2 consecutive events.

P0707

Position 1orPosition 2=Less than 0.127 V - For greater than 1 s & For 2 consecutive events.

P0708

Position 1orPosition 2=Greater than 4.87 V - For greater than 1 s & For 2 consecutive events.

P0851

Engine Control Module - Vehicle Speed Detected=Greater than 10 km/h (6 MPH) & Park/Neutral Position Switch=Park/Neutral - For greater than 2 s

Actions Taken When the DTC Sets

DTCs listed in the DTC Descriptor Category=Type A DTC - Exceptions listed below - Additional actions taken:

- Transmission Learn=Disabled

- Transmission gear allowed=3rd Gear - After a stop

- Engine Cranking=Disabled

DTC P0851=Type C DTC

Engine Cranking=Disabled

Conditions for Clearing the DTC

DTCs listed in the DTC Descriptor Category=Type A DTC - Exceptions listed below

DTC P0851=Type C DTC

Reference Information

Schematic: Reference

Refer to Automatic Transmission Controls Wiring Schematics

Connector End View: Reference

Refer to Component Connector End View Index

Component View: Reference

Refer to Disassembled Views

Description and Operation

- Refer to Electronic Component Description

- Refer to Transmission General Description

Electrical Information: Reference

- Refer to Circuit Testing

- Refer to Connector Repairs

- Refer to Testing for Intermittent Conditions and Poor Connections

- Refer to Wiring Repairs

DTC Type: Reference

Refer to Powertrain Diagnostic Trouble Code (DTC) Type Definitions

Scan Tool: Reference

Refer to Control Module: References

Circuit/System Verification

1. Ignition - On / Vehicle - In Service Mode

2. Verify there are no DTCs set related to the following system/component:K173 Transmission Range Control Module - If equipped

- If any DTC is set

Refer to: Diagnostic Trouble Code (DTC) List - Vehicle

- Go to next step: If no DTC is set

3. Transmission - Park

4. Verify the scan tool parameter: Park/Neutral Position Switch@K20 Engine Control Module=Park

- If not the specified state

Refer to Circuit/System Testing

- Go to next step: If the specified state

5. Transmission - Neutral - Brake Applied

6. Verify the scan tool parameter:Park/Neutral Position Switch@K20 Engine Control Module=Neutral

- If not the specified state

Refer to Circuit/System Testing

7. Transmission - Park

8. Verify the scan tool parameter: Transmission Range Switch@K71 Transmission Control Module=Park

- If not the specified state

Replace the component: K71 Transmission Control Module

- Go to next step: If the specified state

9. Operate the component: S3 Transmission Shift Lever

Verify the scan tool parameter: Transmission Range Switch=Matches the selector lever position

- If not the specified state

Replace the component:K71 Transmission Control Module

- Go to next step: If the specified state

10. Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

Verify the DTC does not set.

- If the DTC sets

Refer to Circuit/System Testing

- Go to next step: If the DTC is not set

11. All OK.

Circuit/System Testing

NOTE: Circuit/System Verification must be performed before proceeding with Circuit/System Testing.

1. Ignition/Vehicle & All vehicle systems - Off.

2. Disconnect the electrical connector:X1 @K71 Transmission Control Module.

3. Ignition - On / Vehicle - In Service Mode.

4. Test for greater than 9 V between the test points: Signal circuit terminal 5 & Ground.

- If less than 9 V

- Disconnect the electrical connector:X1@K20 Engine Control Module

- Test for infinite resistance between the test points: Signal circuit

terminal 5@Component harness &

Ground

- If less than infinite resistance

Repair the short to ground on the circuit.

- Go to next step: If infinite resistance

- If less than infinite resistance

- Test for less than 2 ohms between the test points:

- If 2 ohms or greater

Repair the open/high resistance in the circuit.

- If less than 2 ohms

Replace the component:K20 Engine Control Module

- If 2 ohms or greater

- Go to next step: If greater than 9 V

5. Ignition/Vehicle - Off.

6. Test for less than 1 V between the test points: Signal circuit terminal 5@Component harness & Ground.

- If 1 V or greater

Repair the short to voltage on the circuit.

- Go to next step: If less than 1 V

7. Test or replace the component: Park/Neutral Position Switch

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair: Refer to Diagnostic Repair Verification

- Refer to Transmission Control Module Replacement

- For control module replacement, programming, and setup: Refer to Control Module: References