Buick Regal: Vent Hose Replacement

Removal Procedure

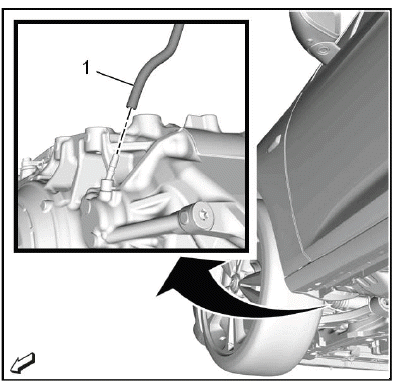

1. Raise and support the vehicle. Lifting and Jacking the Vehicle.

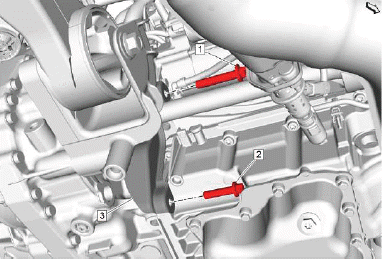

2.

Transmission Vent Hose (1) @Transmission - Disconnect.

3. Lower the vehicle.

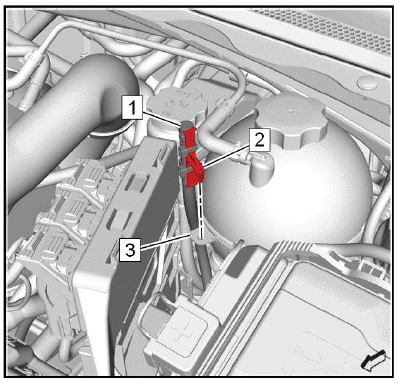

4.

Unclip the vent hose retainer (2) from the radiator surge tank (3).

NOTE: Note the routing of the vent hose.

5. Transmission Vent Hose (1) - Remove.

Installation Procedure

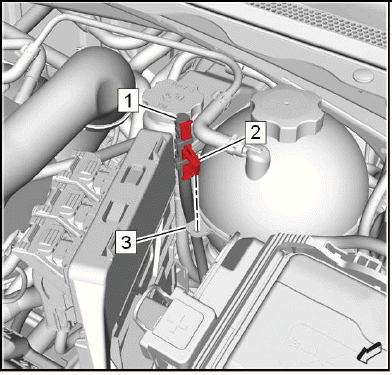

1.

NOTE: Ensure the vent hose is free of kinks and routed clear of sharp objects.

Transmission Vent Hose (1) - Install.

2. Clip the vent hose retainer (2) in the radiator surge tank (3).

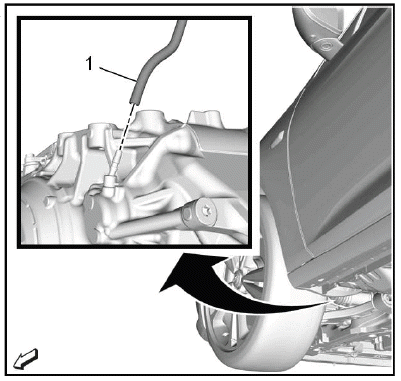

3. Raise the vehicle.

4.

Transmission Vent Hose (1) @Transmission - Connect.

5. Lower the vehicle.

TORQUE CONVERTER FLUID SEAL REPLACEMENT

Special Tools

- DT-586 Remover Hook

- DT-21128 Pinion Seal Installer

- GE-6125 - 1B Slide Hammer

Equivalent regional tools: Refer to Special Tools

Removal Procedure

1. Transmission - Remove - Refer to Transmission Replacement.

2. Torque Converter - Remove - Refer to Torque Converter Replacement.

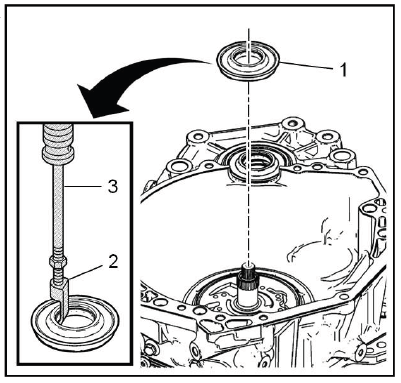

3.

Torque Converter Fluid Seal (1) - Remove and DISCARD - Use the special tool: GE-6125 - 1B slide hammer (3) & DT-586 hook (2)

Installation Procedure

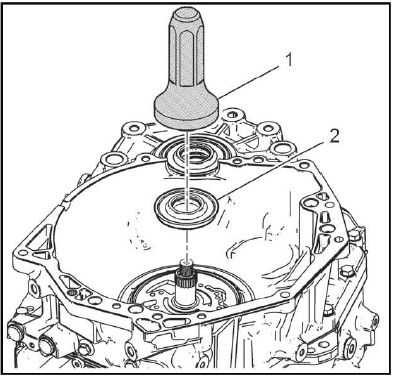

1.

Torque Converter Fluid Seal (2) - Install NEW - Use the special tool: DT-21128 installer (1).

2. Torque Converter - Install - Refer to Torque Converter Replacement.

3. Transmission - Install - Refer to Transmission Replacement.

4. Reset the learned values of the transmission control module. Learned Values Reset.

5. Learn the gear selector neutral position. Gear Selector -N- Position Learn.

TRANSMISSION CONVERTER COVER REPLACEMENT

Preliminary Procedure

Refer to Lifting and Jacking the Vehicle.

- Transmission Rear Bolt

CAUTION: Tighten the transmission converter cover carefully to prevent it from becoming deformed. A deformed transmission converter cover may wear on the starting ring gear or the front wheel drive shaft resulting in noise emission and improper protecting properties.

CAUTION: Refer to Fastener Caution

Tighten 60N.m (44 lb ft)

- Transmission Lower Bolt

CAUTION: Tighten the transmission converter cover carefully to prevent it from becoming deformed. A deformed transmission converter cover may wear on the starting ring gear or the front wheel drive shaft resulting in noise emission and improper protecting properties.

Tighten 40N.m (30 lb ft)

- Transmission Converter Cover

TORQUE CONVERTER REPLACEMENT

Removal Procedure

1. Transmission - Remove - Refer to Transmission Replacement.

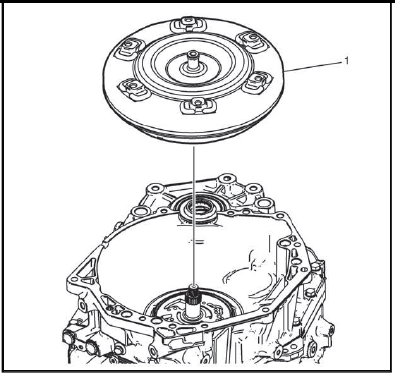

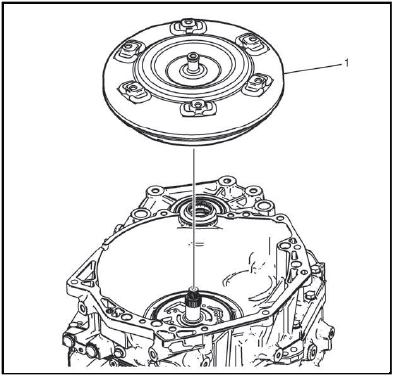

2.

Torque Converter (1) @Transmission - Remove.

Installation Procedure

1.

Torque Converter (1) @Transmission - Install.

2. Transmission - Install - Refer to Transmission Replacement.

3. Reset the learned values of the transmission control module. Learned Values Reset.

4. Learn the gear selector neutral position. Gear Selector -N- Position Learn.