Buick Regal: Symptoms - Engine Mechanical

Strategy Based Diagnostics

1. Perform the Diagnostic System Check - Vehicle before using the symptom tables, if applicable.

2. Review the system operations in order to familiarize yourself with the system functions. Refer to Disassembled Views, Engine Component Description, and Lubrication Description.

All diagnosis on a vehicle should follow a logical process. Strategy based diagnostics is a uniform approach for repairing all systems. The diagnostic flow may always be used in order to resolve a system condition. The diagnostic flow is the place to start when repairs are necessary.

Visual/Physical Inspection

- Inspect for aftermarket devices which could affect the operation of the engine.

- Inspect the easily accessible or visible system components for obvious damage or conditions which could cause the symptom.

- Check for the correct oil level, proper oil viscosity, and correct filter application.

- Verify the exact operating conditions under which the concern exists. Note factors such as engine RPM, ambient temperature, engine temperature, amount of engine warm-up time, and other specifics.

- Compare the engine sounds, if applicable, to a known good engine and make sure you are not trying to correct a normal condition.

Intermittent

Test the vehicle under the same conditions that the customer reported in order to verify the system is operating properly.

Symptom List

Refer to a symptom diagnostic procedure from the following list in order to diagnose the symptom:

- Base Engine Misfire without Internal Engine Noises

- Base Engine Misfire with Abnormal Internal Lower Engine Noises

- Base Engine Misfire with Abnormal Valve Train Noise

- Base Engine Misfire with Coolant Consumption

- Base Engine Misfire with Excessive Oil Consumption

- Engine Noise on Start-Up, but Only Lasting a Few Seconds

- Upper Engine Noise, Regardless of Engine Speed

- Lower Engine Noise, Regardless of Engine Speed

- Engine Noise Under Load

- Engine Will Not Crank - Crankshaft Will Not Rotate

- Engine Compression Test

- Turbocharger Leaking Fluids Externally

- Turbocharger Noise

- Turbocharger Smoke or Smell

- Turbocharger Loss of Boost Pressure

- Oil Consumption Diagnosis

- Oil Pressure Diagnosis and Testing

- Oil Leak Diagnosis

- Drive Belt Chirping, Squeal, and Whine Diagnosis

- Drive Belt Rumbling and Vibration Diagnosis

- Drive Belt Falls Off and Excessive Wear Diagnosis

- Drive Belt Tensioner Diagnosis

BASE ENGINE MISFIRE WITHOUT INTERNAL ENGINE NOISES

.png)

.png)

.png)

BASE ENGINE MISFIRE WITH ABNORMAL INTERNAL LOWER ENGINE NOISES

.png)

BASE ENGINE MISFIRE WITH ABNORMAL VALVE TRAIN NOISE

.png)

BASE ENGINE MISFIRE WITH COOLANT CONSUMPTION

.png)

BASE ENGINE MISFIRE WITH EXCESSIVE OIL CONSUMPTION

.png)

ENGINE NOISE ON START-UP, BUT ONLY LASTING A FEW SECONDS

.png)

.png)

UPPER ENGINE NOISE, REGARDLESS OF ENGINE SPEED

.png)

.png)

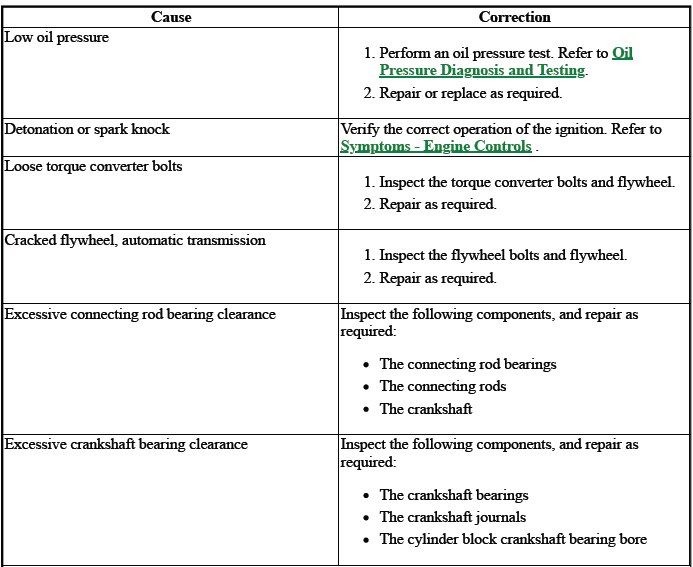

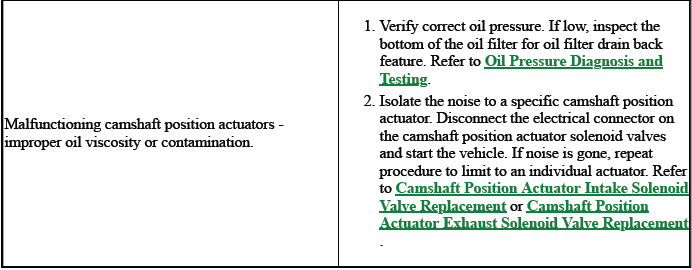

LOWER ENGINE NOISE, REGARDLESS OF ENGINE SPEED

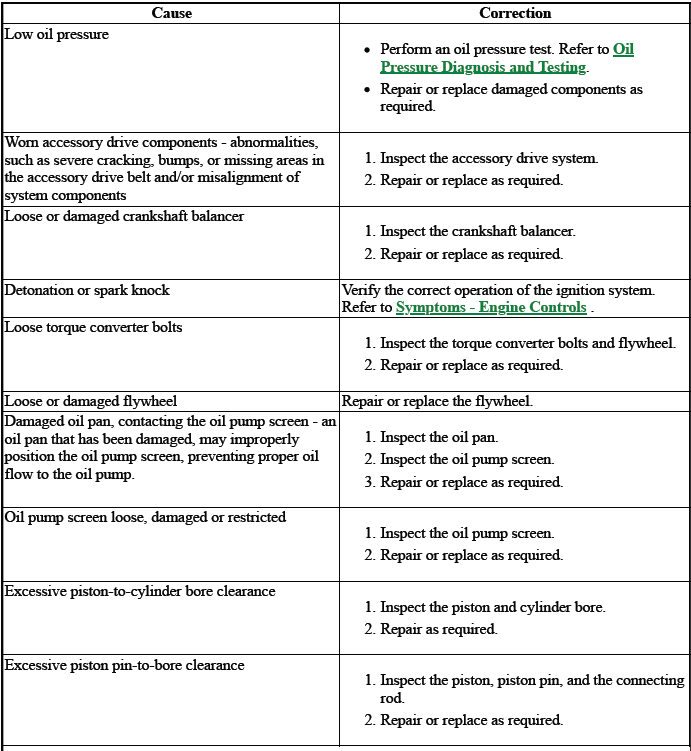

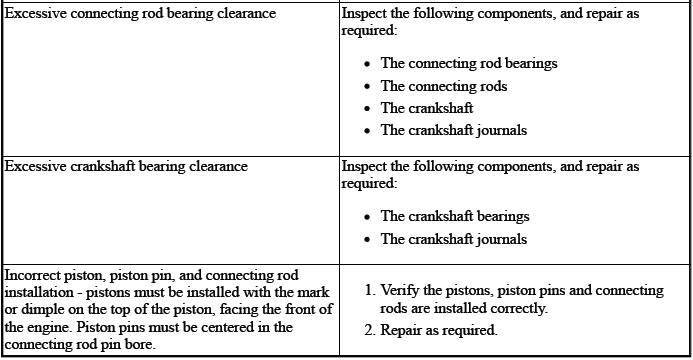

ENGINE NOISE UNDER LOAD

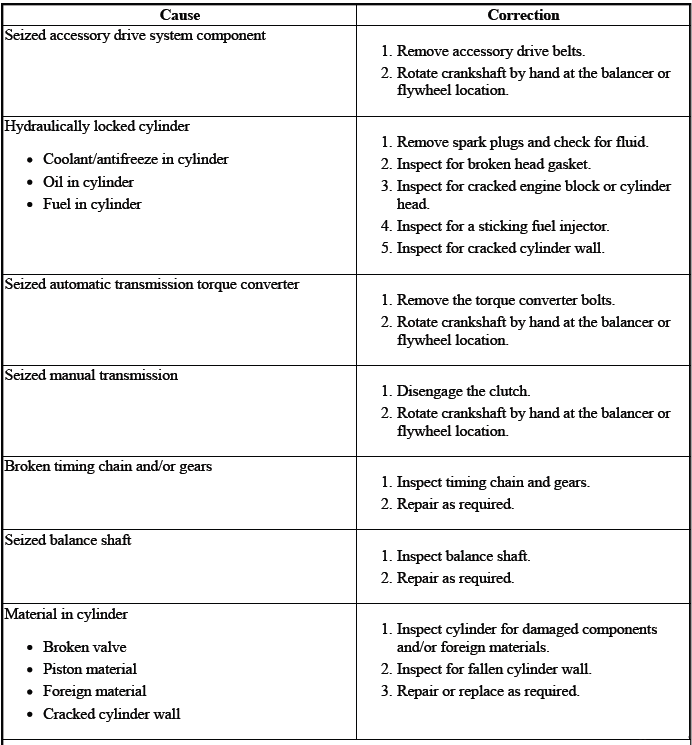

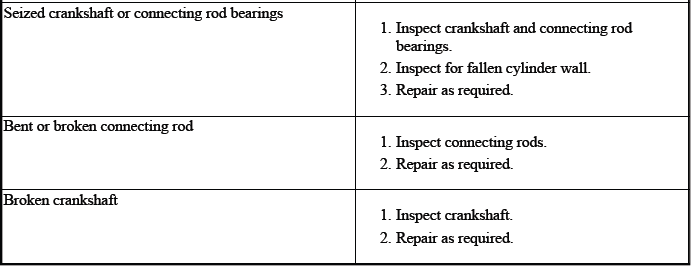

ENGINE WILL NOT CRANK - CRANKSHAFT WILL NOT ROTATE